- Geotechnical materials t...

- Waterproof material test...

- Bridge expansion joint t...

- Mask protective clothing...

- Mechanical properties te...

- Textile material testing...

- Dyeing and finishing clo...

- Down and feather testing...

- Labor protection protect...

- Leather and shoe materia...

- Zipper button testing eq...

- Other material testing e...

- Fiber yarn testing equip...

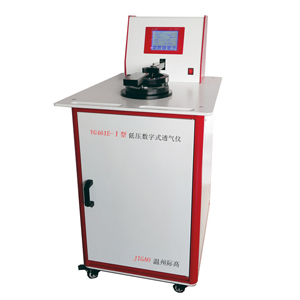

| YG461E-Ⅰ Low Pressure Air Permeability Meter |

|

【Scope of application】 The low-pressure digital air permeability meter is used to test the air permeability of various sheet materials such as coated fabrics, filter paper, filter media, and plastics. 【Standards compliant】 GB/T 5453-1997 Textiles Determination of fabric breathability ISO9237-1995 Textiles Determination of Fabric Air Permeability BS EN ISO9237-1995 Textiles Determination of air permeability of fiber fabrics DIN EN ISO9237-1995 Textiles Determination of air permeability of fiber fabrics EN ISO9237-1995 Textiles Determination of air permeability of fiber fabrics ASTM D737-2004 (2012) Test Method for Air Permeability of Textiles JIS L1096-8.26A:2010 General Textile Test Method ISO9073-15: 2007 Textiles and Nonwovens Test Methods Part 15 Determination of Air Permeability BS EN ISO9073-15: 2008 Textiles Nonwovens Test Methods Part 15 Determination of Air Permeability DIN EN ISO9073-15: 2008 Textiles Nonwovens Test Methods Part 15 Determination of Air Permeability EN ISO9073-15: 2008 Textiles and Nonwovens Test Methods Part 15 Determination of Air Permeability BS 3424-16-1995 Coated fabric testing. Part 16 Determination of air permeability GB/T 13764-1992 Test method for permeability of geotextile GB/T 22819-2008 Determination of Air Permeability of Highly Air Permeable Paper QB/T l461-1992 Determination of air permeability of highly air permeable paper JIS K6400-7-2004 Determination of physical properties of flexible porous polymer materials Part 7 Air permeability AFNOR G07-111, BS 5636, DIN 53887 and other air permeability performance standards 【technical parameter】 1 Pressure range: 0~300Pa self-set pressure drop 2 Measurable air permeability: 0.1~4000mm/s 3 Measurement error: ≤±2% 4 Measurable fabric thickness: ≤15mm 5 Adjustment of suction volume: dynamic adjustment of data feedback 6 Fixed value circle of sample area: 5cm2; 20cm2; 50cm2; 100cm2; four 7 Fixed value circle of sample diameter: Ф50mm (≈19.6cm2) Ф70mm (≈38.5cm2) 8 Spray mouth: 11 in total 9 Data processing volume: ≤1000 tests 10 Data output: high-definition touch screen display; built-in micro printer; 11 Electricity source: AC 220V±10V 50Hz 12 Power consumption: 2000W 13 Weight: 80Kg 14 External shape: 600×700×1100mm (L×W×H) |